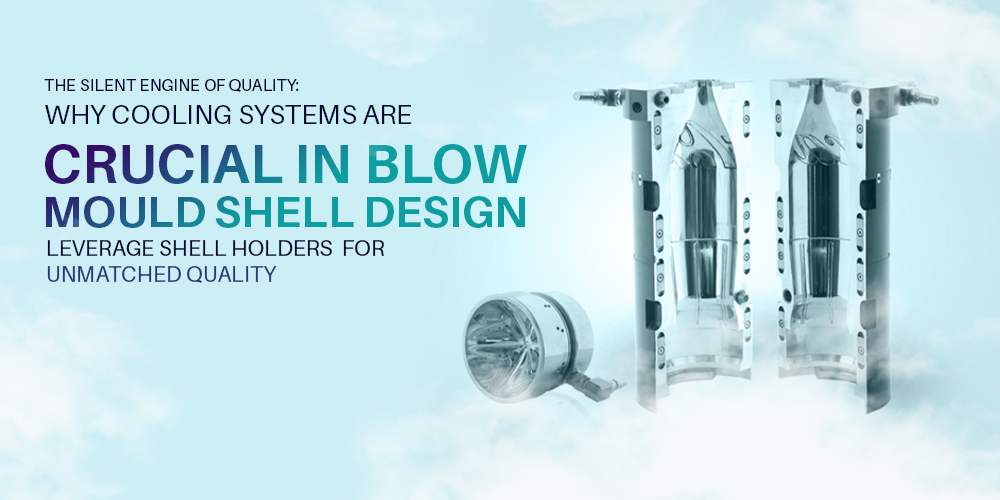

In the competitive world of plastic packaging, speed and precision are non-negotiable. While the latest blow moulding machine technology and advanced materials get the spotlight, there is a hidden, foundational element that dictates both product quality and production efficiency: the cooling system in the blow mould shell.

For industry leaders and manufacturers striving for zero-defect production and optimised cycle time reduction, understanding the science and engineering behind effective mould cooling is paramount. At Awanti Polymoulds, we engineer our PET blow moulds and plastic bottle moulds with advanced cooling channels designed to meet the rigorous demands of modern manufacturing.

Why Effective Cooling is the Foundation of Blow Moulding Success

The blow moulding process involves heating a plastic preform or parison to a pliable state and then inflating it to conform to the shape of the mould cavity. The final, critical step is solidification—and this is where the cooling system takes centre stage.

1. Mastering Dimensional Stability and Part Quality

- The Warping Challenge: Uneven or inadequate cooling is the primary culprit behind defects like warping, non-uniform wall thickness, and excessive shrinkage. When parts cool at different rates, internal stresses build up, compromising the container’s final shape and structural integrity.

- The Awanti Solution: Our precision moulds feature strategically placed, high-efficiency cooling channels that ensure uniform cooling across the entire mould surface. This guarantees dimensional accuracy, a key factor for bottling lines and packaging aesthetics.

2. Accelerating Cycle Time for Maximum Productivity

- Aesthetic Appeal: For products like clear cosmetic or beverage containers, a flawless surface finish is crucial. Controlled cooling prevents surface defects like hazing or dull spots, ensuring a premium visual quality.

- Structural Integrity: The cooling rate significantly affects the plastic’s crystallisation structure. Proper blow mould temperature control allows the material to solidify with the desired balance of strength, impact resistance, and barrier properties, extending the product lifespan.

3. Enhancing Surface Finish and Mechanical Properties

- The Efficiency Equation: In high-volume PET bottle manufacturing, the cooling phase can account for up to 60-90% of the total moulding cycle time. Simply put, faster, more efficient heat transfer directly translates to higher output.

- Trending Keywords to Watch: Manufacturers are prioritising solutions that offer cycle time optimisation and enhanced cooling efficiency. This often involves innovative mould materials and advanced coolant flow management to quickly dissipate heat, boosting your overall manufacturing efficiency.

The Latest Trends in Cooling System Design

Modern blow-mould shell design incorporates sophisticated technology to move beyond simple cooling lines. Staying ahead of these trends is essential for blow mould manufacturers in India and globally:

- Internal Cooling Systems: Techniques utilising chilled air, liquid nitrogen, or are injected directly into the parison/preform during blowing. This drastically reduces the cooling differential between the outer and inner walls of the plastic, achieving significant cycle time reduction (sometimes up to 50%) and preventing product warpage.

- Advanced Mould Tooling: Using materials with superior thermal conductivity and integrating complex, efficient channel layouts through Precision Engineering and sometimes 3D Printing for conformal cooling is becoming the new industry standard for high-performance moulds.

- Smart Temperature Control: The integration of IoT-enabled sensors and AI-driven process optimization is making cooling systems “smart.” These systems offer real-time temperature monitoring and dynamic adjustments to maintain optimal conditions, minimizing human error and ensuring consistent quality.

Partner with Awanti Polymoulds for Cooling Excellence

At Awanti Polymoulds, we don’t just build moulds; we engineer cooling solutions that power your production line. As a leading Blow Mould Manufacturer in India, our commitment to precision machining and advanced mould technology ensures that your final product achieves the highest standards of quality, consistency, and structural integrity.

By focusing on the critical role of cooling in your blow mould shell design, we help you reduce scrap, shorten cycles, and maximise your profitability.

Ready to boost your production output and product quality? Explore our range of high-efficiency PET Blow Moulds & Plastic Bottle Mould solutions designed for the future of packaging.

Visit our Products Page to learn more about our Quick Change Moulds, Linear Moulds, and Shell Holder solutions, or Contact Us for a consultation on your specific cooling requirements.

FAQ's

What is the main purpose of a cooling system in a blow mould?

The main purpose is to remove heat from the molten plastic (parison or preform) rapidly and uniformly, allowing it to solidify into the final desired shape. This is critical for dimensional stability, achieving the required mechanical properties, and significantly reducing the overall moulding cycle time.

How does poor cooling affect the final product quality?

Inadequate or uneven cooling leads to various defects, including:

Warping and Distortion: Uneven shrinkage across the part.Internal Stress: Compromising the product's long-term strength and durability.Poor Surface Finish: Defects like hazing or sink marks.Inconsistent Wall Thickness: Leading to structural weakness.What modern technologies are used to improve blow mould cooling efficiency?

Key advancements include:

Internal Cooling: Using super-chilled media (air, liquid) inside the prison.Conformal Cooling: Mould cooling channels created via 3D Printing that closely follow the contour of the mould cavity.Smart Temperature Control: Utilising IoT sensors and feedback loops for real-time temperature monitoring and automatic adjustment.How much of the total cycle time does the cooling phase typically take in blow moulding?

The cooling phase is often the longest part of the process, typically accounting for 60% to 90% of the total blow moulding cycle time, especially for thick-walled or large containers. Optimising this phase is the most effective way to increase production throughput.

Why is uniform cooling so important for Awanti Polymoulds' PET blow moulds?

For PET blow moulds, uniform cooling is essential for controlling the material's crystallisation and orientation. This ensures the final bottle has the maximum clarity, optimal barrier properties, and the precise dimensional accuracy required for high-speed filling lines and consistent stacking strength. Awanti Polymoulds focuses on engineered channel design to deliver this uniformity.