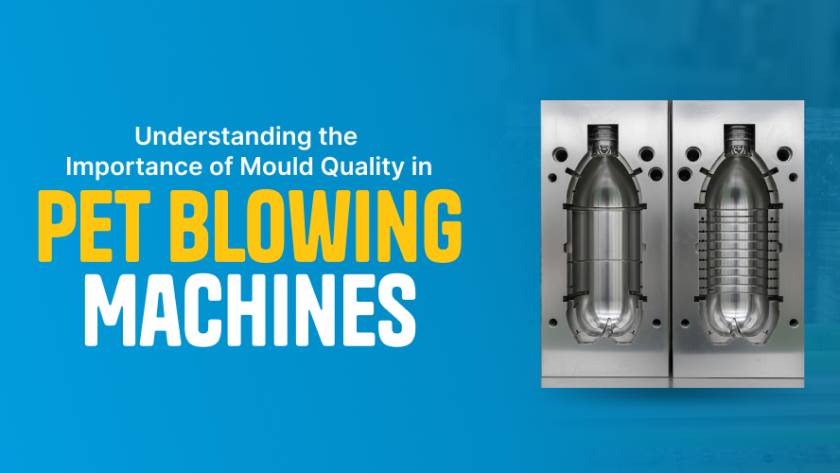

In the dynamic world of plastic packaging, where speed, accuracy, and sustainability are paramount, PET (Polyethene Terephthalate) bottle manufacturing stands at the forefront. As consumer demand for lightweight, durable, and recyclable containers grows, the technology behind producing the perfect PET bottle becomes more critical than ever. At the heart of this process lies the mould,…