A manufacturing company is known for the quality of products it manufactures. Along with the quality, factors such as durability of the product, the life of the product and the materials utilized are also very important.

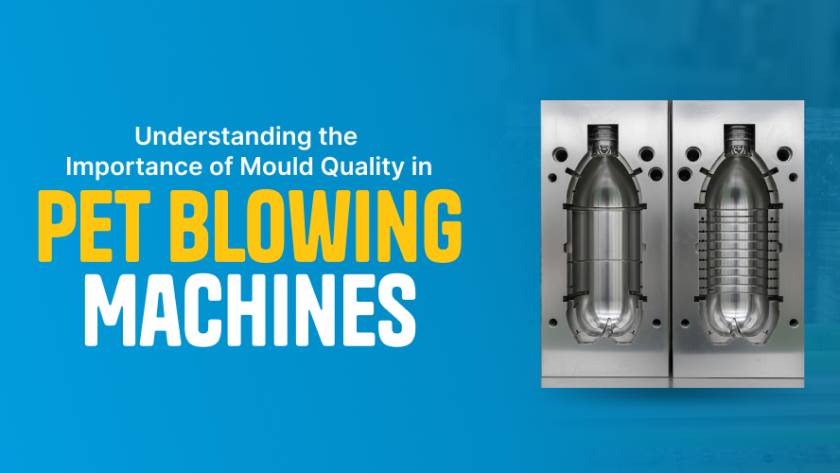

Plastic bottles and containers have a wide variety of applications in the beverage industry, food processing industry, pharmaceutical industry, liquor industry and home care products. Plastic bottles and containers are used for the packaging of water, soda, juice, oil, jams, confectionary, medicines, liquor and personal and home care products. The size of containers varies from a few hundred millimetres to several litres.

The products we build stand the test of time and are durable, sturdy and of best quality. An important aspect in the beverage industry is quality. A good bottle always lays the foundation of a great brand. The customer identifies and recognises the product mostly through its quality, hence it becomes the matter of utmost importance to make the product retain the best quality.

In today’s age plastic is seen everywhere- be it interiors, packaging industry, medical world or even the world of kitchen utensils. Plastic is a non-metallic substance that can easily be moulded into desired shape. It can be melted and then cooled down into the required structure for commercial use. Even the keyboard that you type on or the mobile that you utilise are made up of plastic.